From farm to fork

Traceability of food from farm to fork is the buzzword in food technology. Second Thought uses a digital twin to…

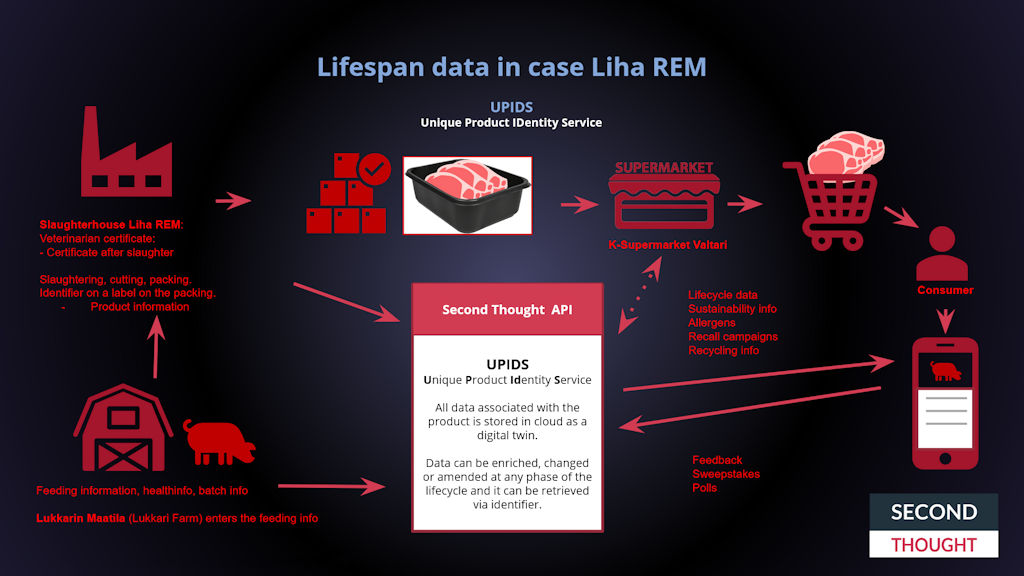

Traceability of food from farm to fork is the buzzword in food technology. Second Thought uses a digital twin to carry information, and it works a bit like a packing list pocket outside a cardboard box. UPIDS of Second Thought is a world-class traceability service in terms of accuracy and ease. The Service had its world premiere in June 2021 with pork meat packings from the local Lukkari Farm sold in Kouvola’s K-Supermarket Valtari.

Food traceability has been in development all over the world for a long time and has been pursued in various ways. There has not been an all-encompassing system that suits everyone, nor is there proper clarity on how the chain could be covered. During the journey, the identifier needs to collect a lot of data, so how does that happen and where is the information stored? In 2018, Second Thought, a start up from Lahti, Finland, developed a unique product identification system, which enables packages to be monitored individually. Second Thought’s UPIDS system uses a digital twin stored in the cloud to store and transport information associated with the package.

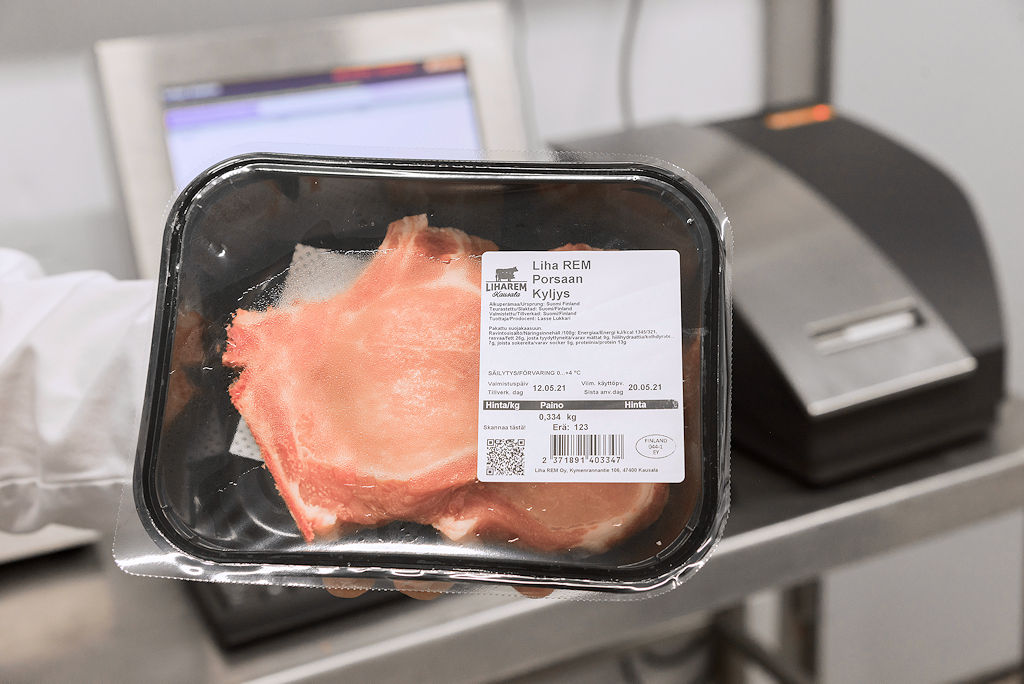

A traditional EAN or barcode identifies a product as different from other products at the article level, i.e. the same EAN or barcode on all packages of that same product. UPIDS now identifies the product at the piece level. The pork package completed from the production line receives its own unique code, which differs from the code of the next completed package. This way, each package has its own unique QR identifier even though every package has the same barcode.

Jake Laisi, chief technology officer of Second Thought, had his previous career at Nokia and Microsoft. In 2017 he came up with the idea that unique product traceability is best done with a digital twin, and a URL QR code works best as a link between the physical object and its digital twin. He developed a proprietary URL-QR code standard for Second Thought that allows products to be identified and tracked, and it also includes offline-readable date information. UPIDS was built around this innovation and the system has been systematically developed for three years.

Last year the global standardization organization GS1, who manages the use of barcodes, published a new standard for the URL QR code and named it GS1 Digital Link. The standard specifies what the identification code contains in numbers or letters and in what order. GS1 Digital Link is a very similar identifier compared to UPIDS: since it is quite close to the original UPIDS code and the transfer is easy, Second Thought decided to adapt to that as well for global compatibility. Obviously, the same identifier solution had been reached elsewhere, and Second Thought is cutting edge, with a considerable lead.

However, the GS1 Digital Link code standard has no data processing, information system or data transfer. Second Thought had such an information system already developed. GS1 is like a municipality that names the streets and gives the numbers to houses. Second Thought is now like a post office that collects mail and transports and delivers it to those addresses.

Step by step, the parts of UPIDS were piloted in several stages. Bakery Rosten in Turku started piloting the individual labelling of seed crisp bread packages over a year ago in January 2020. At the same time, grocery hypermarket K-Citymarket Heinola updated the meat and fish service counter scales software to print UPIDS QR code.

On the right: Service counter scale prints QR-codes to over the counter packages

– Of course, each phase of the pilot is laborious to get running for the first time, but the repeatability, i.e., scaling, is easier after that, says Jani Kasanen, CEO of Second Thought. It was at Mr. Kasanen’s request that Jake Laisi initially started to develop a system suitable for tracking sell-by-dates of individual perishable food packages. Kasanen has previously worked as a grocery retailer for fifteen years for Finland’s grocery giant Kesko.

Additional self-monitoring systems for service counter scales have also been running since summer 2020, and the chain links were now brought together when Lukkari Farm in Kouvola started sending their farm feeding information to the slaughterhouse along with the animals. With the UPIDS identifier, the slaughterhouse Liha REM in Kausala, Iitti, labels the information on pre-packaged pork packages that are forwarded to the store. The information is utilized by K-Supermarket Valtari in the center of Kouvola and packages with UPIDS-identifiers go to other grocery stores in the area as well.

Tracking chain

On the Internet of Things (IoT), a digital twin refers to the digital equivalent of a physical product on a server or in the cloud. The digital twin can be used to manage, change, and share information related to its physical counterpart. The twin is widely used on the engineering side, Second Thought now brings the twin to groceries as well.

Second Thought UPIDS traceability works so that the batch of pigs from the farm through the slaughterhouse to the store is tracked and the information in various points is stored in the digital twin of the identifier.

The pigs are raised at Lukkari Farm in Myllykoski, Kouvola, and the main raw materials for pig food are produced on the farm’s own and neighbouring fields. When the pigs leave for the slaughterhouse, they are accompanied by, via mobile application, a batch identifier on which a digital twin has been created to store the data. The batch identification contains e.g. nutrition information and the certificate issued by the final veterinary inspection. The producer inputs the origin and the pig food information.

After slaughtering, a standard sticker label with a QR code in the corner is printed on the finished packages at the cutting plant’s packing centre. This optically readable identifier acts as a door to Second Thought’s UPIDS system and is connecting the package and the digital twin in the cloud. The consumer can read the digital product information by scanning the QR code with their smart device. The system collects the information on the origin of the pigs and the veterinary examination certificate, as well as all the individual information stored in the product, for direct viewing.

The code is scanned, for example, with a smartphone and the scanning automatically opens a web page on which the tracking data of the digital twin is shown. No separate application is required for reading: on most smart devices it automatically opens in a web browser by scanning the QR code with the camera of the device.

There are competitors in the traceability sector, and it is seen as a good thing: – It shows that there is demand for traceability and consumers are seeking more information about groceries, their origin and responsibility, says CEO Kasanen. However, there are a variety of limitations in competitors’ systems that Second Thought has solved with the help of the digital twin.

– We have made it possible that, in theory, any information can be attached to individual food packages at the packaging stage. Pre-printed packaging is often printed months in advance and even normal self-adhesive labels are very static. The UPIDS identifier, on the other hand, can be used with great flexibility and information on origin can be exchanged at the packing plant many times during the day if raw material batches vary, Mr. Kasanen says.

– UPIDS is a very dynamic digital product information channel: even a product recall warning can be added to the information afterwards. That way the consumer may receive a warning when scanning the QR code before using the product, Kasanen advises. – And if the consumer wants to send feedback to the manufacturer, there is a message field that is automatically accompanied by the unique identifier of the product. For example, possible manufacturing defects can be timed very accurately and effortlessly, Mr. Kasanen says.

QR codes already exist in many product packages and advertisements, but not all QR codes are web addresses: they do not open in a browser and are not aimed at consumers. Web-based QR codes, on the other hand, usually lead to sweepstakes, a company website, or an online store. The actual QR codes for traceability are very rare and often complex to use. That’s why the UPIDS code is made easy: everything opens by a single scan.

Second Thought’s unique identifier carries a lot of information, some for trading systems and some for the consumers. The next step is integration with cash registers, whereby the benefits of the identifier can be made more widely available.

Espera labeling machine existing customers will be happy to know that the UPIDS system can be installed with a normal software update.

UPIDS can also be installed to many other labeller makes. The installation may or may not require a separate Second Thought gateway but should be easy. Please ask.

When purchasing a new labelling machine, please ask for UPIDS Unique Product Identity Service. Second Thought website is www.secondthought.fi . You can also contact Second Thought directly via email: info (at) secondthought.fi

In collaboration with: